PRODUCTS QUALITY

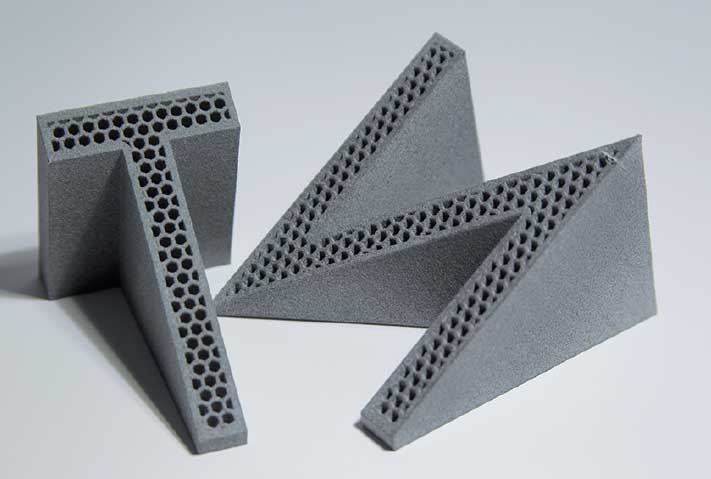

Unleash 3D printing potential

Transform parts proprieties voxel by voxel for a future of applications, materials, and colors without limits.

Imagine a future where we will be able to produce “smart pieces” with incorporated electronic, traceability and intelligence.

We help your company getting ready for the new era of digital production.